Description

The urethane U-cup design provides an excellent heavy-duty seal for both piston or rod applications. Urethane U-cups, commonly known as Disogrin U-cups, work well in both static and dynamic applications.

|

Profiles

|

| Rod Single Lip Unloaded U-Cup

The rod style unloaded U-cup was designed with a shorter, heavier inside sealing lip to achieve a higher initial sealing force on the tube. The rod style unloaded U-cup was developed to extend serviceability and improve reliability in rod sealing.

|

|

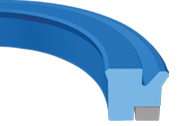

| Rod Double Lip Unloaded U-Cup

The rod style unloaded U-cup is available in a double lip design. The secondary “bump” or lip on the inside heel of the seal provides additional stability in the seal groove. The increased stability enhances the long-term performance of the seal. In rod seal leakage test, the double-lipped rod style unloaded U-cup had better performance then the conventional U-cup. This is due to the initial leakage of the seal is being reduced by the secondary sealing lip.

|

|

| Symmetrical Unloaded U-Cup

This design provides satisfactory service for most rod and piston sealing applications. For more demanding applications with higher temperatures and pressure, other designs should be considered. |

|

| Piston Unloaded U-Cup

The piston style unloaded U-cup was designed with a shorter, heavier outside sealing lip to achieve a higher initial sealing force on the tube. The piston style unloaded U-cup was developed to extend serviceability and improve reliability in piston sealing.

|

|

| Piston Unloaded U-Cup with Anti-Extrusion Ring

Unloaded piston U-cups are also available with anti-extrusion rings. The profile fits a standard u-cup gland, while providing increased extrusion resistance.

|

Design Considerations:

Surface Finish

The chart below provides a general guideline on surface finish.

|

| Static |

8-32 RMS | | Dynamic |

16 RMS | |

Pressure/Velocity

Pressure and velocity are two of the factors that will affect seal integrity. The unloaded urethane U-cup is designed to operate between 0 to 250 feet per minute at 1000-3500 psi. However, the unloaded U-cup can operate at up to 900 feet per minute in low or negligible system pressures. The unloaded urethane U-cup’s performance varies depending on temperature, lubrication, and the chemical environment. Performance capabilities can be extended with the use of an anti-extrusion ring. |

|