|

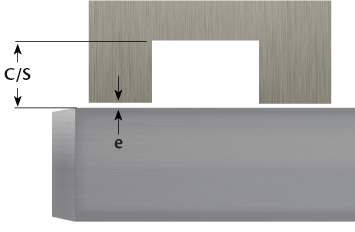

Content 2. DZ Seal Size Charts 3. DZ Seals Description 4. Profiles 5. Part Numbers 6. Design Considerations Extrusion Gap |

Description DZ seals, also known as deep Z-seals, are primarily used for heavy-duty rod applications. These seals combine excellent sealability, low compression set, and superior anti-extrusion characteristics compared to other lip seals. Under low-pressure conditions, the sealing provides its own compressive seal force. As the pressure increases, hydrostatic pressure is mechanically transmitted through the elastomer seal element into the anti-extrusion base. The applied force then deflects radially in a controlled manner, closing the extrusion gap behind the sealing lip. DZ seals are also effective in compensating for high shock loads, such as bucket impacts. DZ seals have various configurations designed to accommodate standard grooves and dimensions within normal manufacturing tolerances. These seals fit into standard deep-loaded U-cup glands. For groove dimensions, please refer to the loaded U-cup section. | |

| Profiles | |

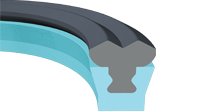

| DZ Seal DZ seal is designed with a greater tolerance to side loading and additional compensation for axial run-out. The double lip design provides greater resistance to compression set and extended life for the elastomeric seal element. DZ seal is ideally suited for dynamic rod applications as the depth of the design provides an increase in stability in higher-pressure applications. |

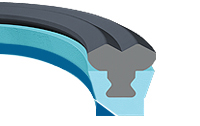

| DZ Seal with Delta Back-Up For applications exposed to severe shock loads or large clearance gaps, the modular "Delta" back-up ring provides the most economical way to close diametrical clearances with additional resistance to extrusion. Positively actuated to control friction, the split Delta design allows ease of installation and retains original seal height and groove depth. |

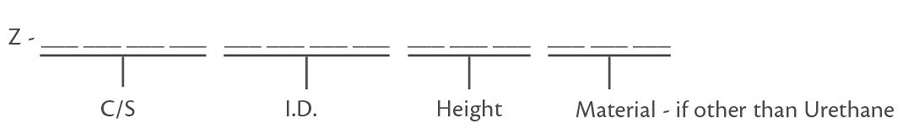

Part Numbers

Example: Z 5000 3000 750 D - Urethane Base, Nitrile Seal Lip, Deep Z-Seal, 1/2" C/S, 3" I.D., 3/4" Height DZ seal standard part numbers are based on urethane base material and nitrile loader. Other popular materials include a Fluorotrel® base, Viton™ loader, and low temperature loader. Go to DZ Seal size charts. | |