|

||

Description de produit U-cups are a lip seal, named for the cross-section's distinctive "U" shape. They are used for both dynamic and static applications. The "U" shape energizes the sealing lips as the application pressure increases. This brilliant design has been modified to create several unique configurations. These modifications provide additional benefits for a variety of applications. The U-cups designs listed below are Hi-Tech Seals' most common designs. | |

| U-Cup Designs |  | Joints en 'u' comblé

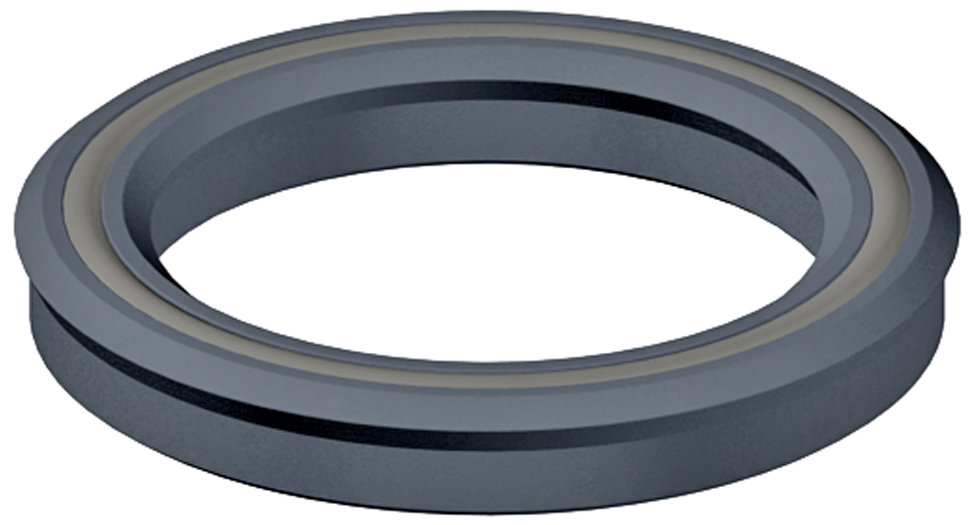

Loaded U-cups are primarily intended for dynamic reciprocating applications. The loaded U-cup is an excellent seal in low pressure rod and piston applications. As the system pressure increases, the loading lip force also increases, automatically compensating for the higher pressure while maintaining a positive seal. Loaded U-Cup Design |

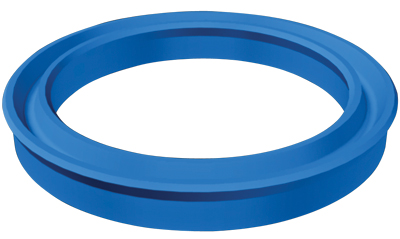

| Garniture en 'u' uréthane The urethane U-cup design provides an excellent heavy duty seal for either piston or rod applications. Urethane U-cups work well in both static and dynamic applications. The unloaded urethane U-cup is commonly known as a Disogrin U-cup. Unloaded Urethane U-Cup Design |

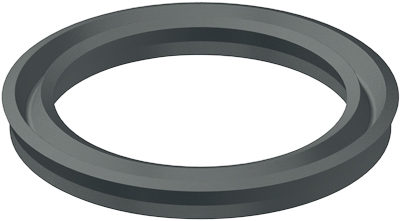

| Joints en 'u' homogène The Homogenous U-cup seal is popular in low pressure applications where a low friction seal would be beneficial. The seal is most commonly used in pneumatic applications as a rod or piston seal. Homogenous U-Cup Design |

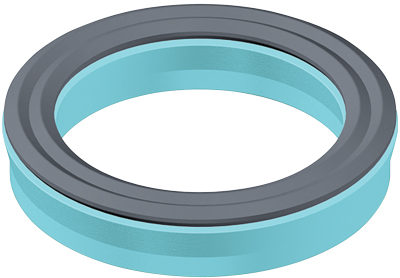

| Joints en 'DZ' DZ seals are squeeze type seals, primarily used for heavy-duty rod applications. DZ seals have excellent sealability, low compression set and superior anti-extrusion characteristics compared to other lip seals. Under low-pressure conditions, the sealing lip provides its own compressive sealing force. DZ Seal Design |

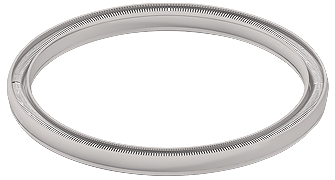

| Joints en coupelle de ressort activé Spring Energized seals are engineered plastic seals which incorporates a metallic spring. The spring loads the seal lips against the mating hardware, creating a seal capable of compensating for movement in dynamic applications Spring Energized Seal Design |