|

| Meeting Your Toughest Demands | ||||

WolCar™ carbide utilizes cobalt and nickel binder agents. Nickel-bonded WolCar™ offers excellent corrosion and wear resistance without compromising strength, making it ideal for harsh environments. Cobalt-bonded WolCar™ provides superior impact resistance compared to its nickel counterpart. It maintains excellent strength at high temperatures and is highly abrasion resistant. Cobalt is widely used for its ability to deliver high strength and toughness. Other binder agents are available upon request. |

|

|||

|

WolCar™ Carbide advantages:

|

|

|||

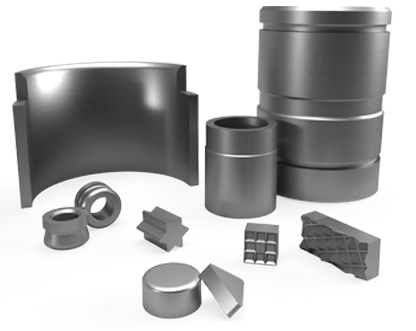

| WolCar™ can be used to create bits, inserts, bushings, poppet bolts, inner sleeves, wear parts, valve parts, sealing rings, MWD components, road milling tools, and more. They are used in markets and industries, including: | ||||

|

|

|||

| WolCar™ carbide is a great solution for your most demanding aplications. Hi-Tech Seals has the experience to assist you in the selection of the proper carbide grade. |

||||