Production |

|

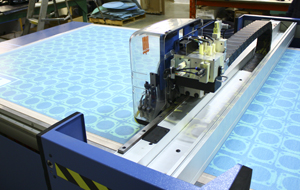

Flashcutter Hi-Tech Seals' Gasket Division's flashcutter is capable of utilizing CAD renderings to quickly produce rubber, plastic and composite materials. We can cut rubber materials up to 1/2" thick and plastic and composite materials up to a 1/8" thick. The surface area of the flashcutter’s can accommodate sheet material up to60"× 120". Dovetailing or skiving techniques allows us to create gaskets the exceed the bed surface area size.

The flashcutters use a rapid vertical reciprocating motion to cut the gaskets. The cutting motion produces a cleaner finished part, avoiding compression marks found on die-cut gaskets. The flashcutters' vacuum surfaces hold sheet material in place preventing the movement of parts during production. This enables the flashcutter to maintain exceptional tolerances. |

|

|

Clicker Press |

Die Cut Hi-Tech Seals' Gasket Division utilizes both a clicker press and roller press to produce die cut gaskets. Dies are manufactured locally and stored in house. Die Cut - Round Gaskets - up to 48” Die Cut - Oblong Gaskets -up to 33” x 66” Hand Cut • Hand Cut Round Gaskets - up to 36”For cost effective small runs, Hi-Tech Seals' Gasket Division produces hand cut gaskets. Dimensional capabilities include:  • Hand Cut - Oblong Rubber Gaskets - up to 48” x virtually endless • Hand Cut - Oblong Non-asbestos Gaskets - up to 60” x 180” |