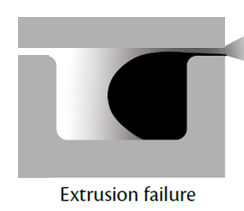

O-rings are among the most widely used sealing solutions in industrial applications due to their simplicity, cost-efficiency, and ease of installation. However, O-rings can experience failure in various ways. One of the most common O-ring failures is extrusion.

What is O-Ring Extrusion Failure?

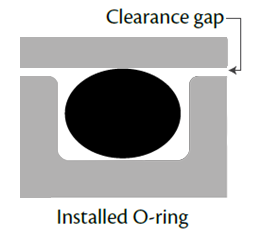

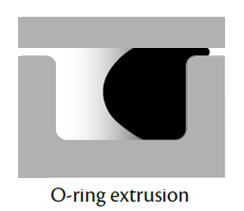

Extrusion occurs when the elastomer is forced into the clearance gap between mating components under high pressure. This causes the material to become visibly nibbled, chipped, or ragged, leaving the O-ring looking tattered, while also negatively affecting the elastomer’s sealing performance.

Causes of Extrusion

Contributing factors to extrusion include:

- Excessive pressure

- Excessive clearances

- Excessive gland fill

- Low modulus or hardness elastomer

- Irregular clearance gaps

- Sharp gland edges

- Improper sizing

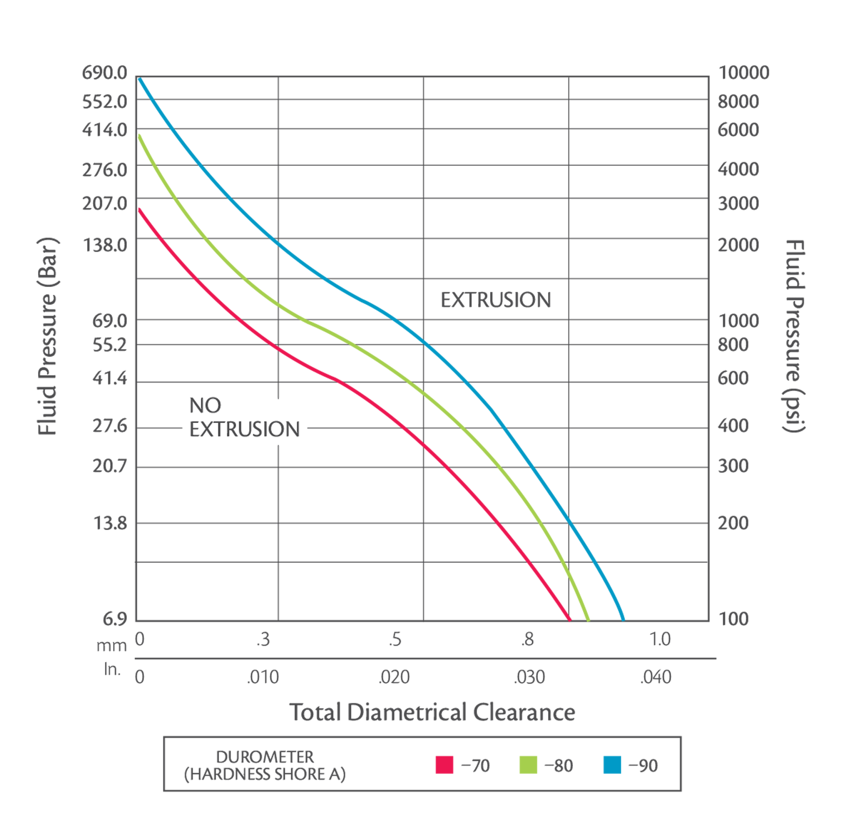

The relationship between fluid pressure, clearance, and durometer is expressed visually in the graph below.

Common Preventions

There are numerous ways to prevent extrusion from occurring. One solution is reducing the clearance gap between the mating components. A reduced clearance gap gives little to no room for the elastomer to extrude. Precision machining can help achieve this tight tolerance.

Proper gland dimensions and correct O-ring sizing are critical, with consideration of gland fill. Gland fill is the percentage of the gland (groove) volume occupied by the compressed O-ring. The gland fill of the installed O-ring should not exceed 85% to allow space for compression, volume swell, and thermal expansion of the O-ring. If gland fill is too high, the O-ring occupies excessive space within the groove, leading to over compression and an increased risk of extrusion. If gland fill is too low, the O-ring may not compress adequately, resulting in an ineffective seal.

Using elastomer materials with a higher hardness durometer helps minimize the risk of extrusion. Harder elastomers are less malleable under high operating pressures, making them less prone to extrusion. In contrast, softer elastomers deform more easily and are more susceptible to being forced into clearance gaps.

Back-Up Rings or sometimes called anti-extrusion rings are an effective way to prevent elastomers from extruding into clearance gaps. These are thin rings made of hard durometer elastomers or hard plastic materials such as KasPex™ PEEK, PTFE, and nylon. Once in place these rings will provide essentially zero clearance. They support the elastomer by increasing its ability to withstand high pressures. A single backup ring is sufficient for one-directional pressure, whereas when pressure is bi-directional, backup rings are recommended on both sides of the O-ring.

Conclusion

Extrusion is preventable when following the correct measures. By understanding these solutions, it will significantly reduce the probability of encountering an O-ring extrusion failure.

If O-Ring extrusion failure occurs, reach out today for support in identifying and preventing this and other O-Ring failures.