Hydraulic seals and pneumatic seals are precision-engineered components used in cylinder systems in static and dynamic applications. They are designed to prevent leakage, protect internal components, and maintain system pressure. Their role is crucial to maintain the efficiency and performance of the system, while extending the cylinder’s life cycle.

Hi-Tech Seals provides an extensive selection of rod seals and piston seals for single-acting and double-acting systems. They are available in numerous materials and lip configurations to suit different pressures, temperatures, media, and application requirements.

Main Functions

1.) Prevent Leakage – These sealing components maintain internal pressure and prevent media leakage by creating pressure barriers between moving parts. Piston seals prevent pressurized media from bypassing to the opposite side of the chamber, while rod seals stop internal media from escaping the cylinder as the rod extends and retracts.

They can adapt to withstand different pressures demanded in the application. When system pressure presses onto the elastomer, it causes the elastomer to expand, conforming to the surfaces being sealed, providing a tighter seal. Back-up rings can help support the elastomer to withstand high pressures by keeping the elastomer in place and preventing it from entering the clearance gap.

2.) Prevent Contamination – Wipers, in particular, act as a barrier to keep dirt and debris out of the cylinder, preventing external contaminants from entering the system and protecting internal components.

Common Seals for Hydraulic and Pneumatic Cylinders

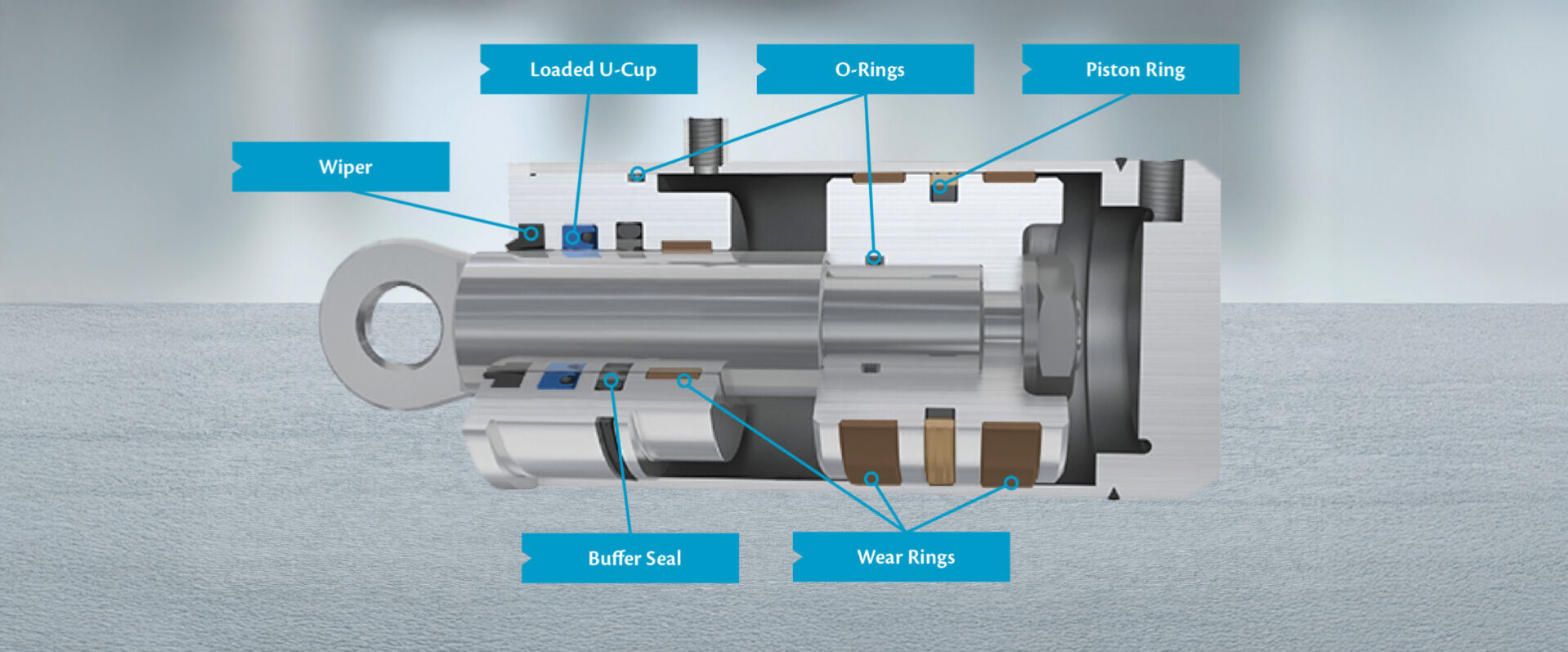

| O-Rings O-Rings grooves allow the O-Ring to be squeezed diametrically out-of-round even before the pressure is applied. The distortion of the O-Rings is a resilient elastic compound that fills the leakage path, thus creating a seal.

|

| Wipers prohibit contaminants from entering the cylinder and damaging the internal seals and components. They scrape the system’s surface when it moves, eliminating any debris or elements that may have gathered. They can also act as a secondary rod seal.

|

| Loaded U-Cups are primarily used for dynamic reciprocating applications. They are an excellent seal in low pressure piston or rod applications. The loading lip forces increases as the system pressure increases, automatically compensating for the higher pressure while maintaining a positive seal. Unloaded U-Cups and Homogenous U-Cups are available as style options.

|

| Wear rings help keep the piston and rod centered and prevent metal-to-metal contact between components. This allows for even distribution of pressures to limit the chances of damaging the components and seals.

|

| Piston rings’ main function is to form a seal between the cylinder rod and piston, preventing lubricants and gases from leaking. They also support the movement of the piston by maintaining the pressure within the cylinder.

|

| Buffer Seals are commonly used in combination with another rod or piston seal, typically a U-cup style seal. Buffer seals in rod applications are designed to absorb pressure fluctuations when working under high-load conditions, which increases the lifespan of a rod seal.

|

| Machined seals provide users with custom sealing solutions to precisely fit their specific requirements. Rapid Seal is Hi-Tech Seals’ in-house elastomer and plastic machining service. Our sealing specialists are able to quickly design and manufacture new, replacement, and prototype components. Customers have the option to select from standard pre-programmed profiles or collaborate with our team to design a precision-machined sealing solution.

|

| Seal kits provide customers with seal replacements to help them stay organized, increase installation efficiency, and simplify the ordering process for cylinder maintenance.

|

Conclusion

These seals play a critical role in hydraulic and pneumatic cylinder performance. Proper seal selection, considering environmental exposure and operating conditions, supports improved cylinder integrity, reliability, and long-term performance. Connect with our sealing specialists to find the right solution for a hydraulic or pneumatic cylinder application.