Description

Homogenous U-cups (block vees) are a non-loaded, single material U-cup. The HU seal is popular in low pressure applications where a low friction seal would be beneficial. The seal is most commonly used in pneumatic applications as a rod or piston seal. The design is suited for situations where space is limited. The HU seal is typically made from an 80 durometer Nitrile but also comes in Viton™/fluorocarbon, Neoprene and other homogenous materials.

As pressure is applied to the homogenous U-cup the seal experiences an increase in sealing force until it reaches the maximum pressure the seal can handle. Homogeneous U-cup seals can handle up to 500 PSI; however, if you have applications that require higher pressure capabilities please consult a Hi-Tech Seals’ sales representative.

|

Profiles

|  | Homogenous U-Cup

The standard homogenous u-cup has a u-shaped groove formed in such a manner that there is an inside and outside sealing lip.

|

|

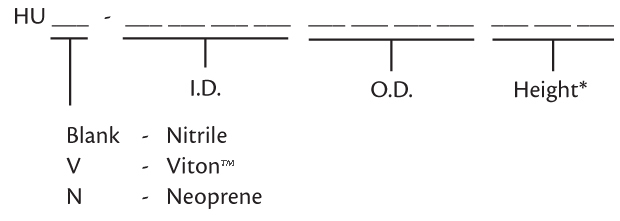

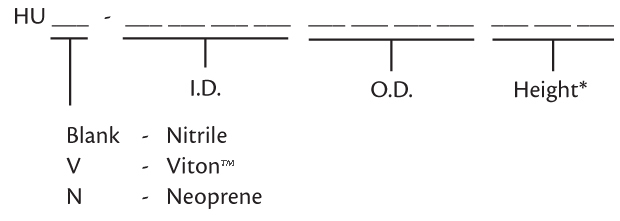

Part Numbers

* Height is only listed if the axial height is greater than the cross-section.

|

| Material: | Temp. Range |

|---|

| Nitrile | -40°C | to | 120°C |

| Viton™/Fluorocarbon | -26°C | to | 204°C |

| Neoprene | -40°C | to | 121°C |

|

Example: HU - 0437 0688 - Nitrile Homogenous U-Cup - 7/16” Nom. I.D., 11/16” Nom. O.D.

Go to Homogenous U-Cup size charts. |

|

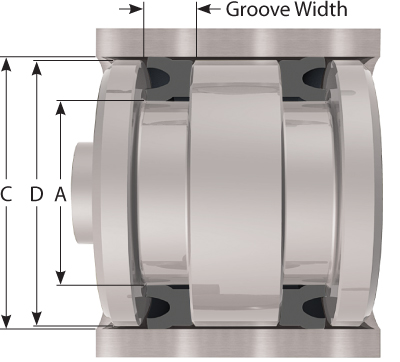

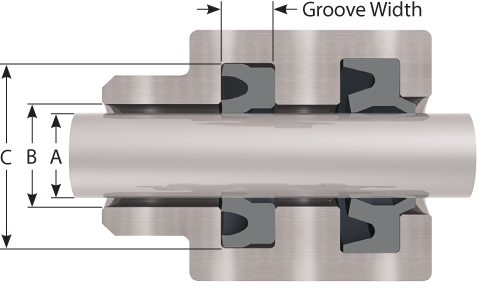

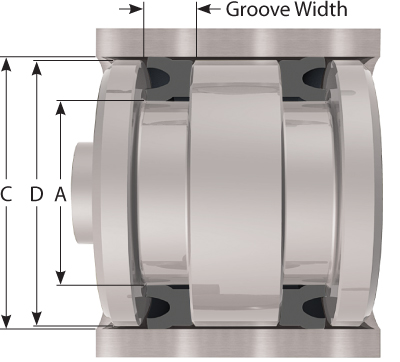

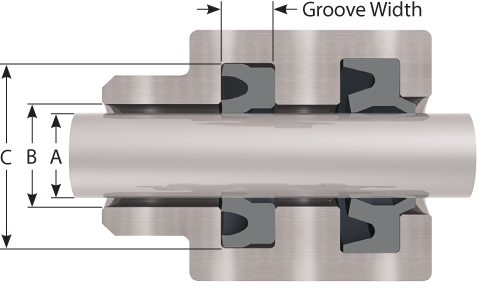

Groove Configuration

|

|

|

A |

B |

C |

D |

Seal I.D. | Dim. |

Groove

Tol. |

Rod

Tol. | Throat Ø | Seal

O.D. | Dim | C. Bore

Tol. | Gland

Tol. | Piston Ø |

Dim | Tol. | Dim | Tol |

0.125 -

1.500 | Nom ID | + 0.000

- 0.001 | + 0.000

- 0.001 | ID + 0.001 | + 0.002

- 0.000 | 0.250 -

2.375 | Nom OD | + 0.003

- 0.000 | + 0.002

- 0.000 | OD - 0.002 | + 0.000

- 0.001 |

1.506 -

2.500 | " | + 0.000

- 0.002 | + 0.000

- 0.001 |

ID + 0.001 |

+ 0.002

- 0.000 |

2.437 -

4.750 |

" |

+ 0.004

- 0.000 |

+ 0.003

- 0.000 |

OD - 0.002 |

+ 0.000

- 0.002 |

2.506 -

8.000 |

" |

+ 0.000

- 0.003 |

+ 0.000

- 0.002 |

ID + 0.001 |

+ 0.003

- 0.000 |

5.000 -

7.750 |

" |

+ 0.004

- 0.000 |

+ 0.003

- 0.000 |

OD - 0.003 |

+ 0.000

- 0.003 |

8.250+ |

" |

+ 0.000

- 0.004 |

+ 0.000

- 0.003 |

ID + 0.002 |

+ 0.004

- 0.000 |

8.000+ |

" |

+ 0.005

- 0.000 |

+ 0.003

- 0.000 |

OD - 0.003 |

+ 0.000

- 0.004 |

Groove Width: The groove width is the seal height + 1/32nd ± 0.010 |

|