Imperial & Metric |

Spring Energized U-Cups are engineered plastic seals which incorporates a metallic spring. The spring loads the seal lips against the mating hardware, creating a seal capable of compensating for movement in dynamic applications. The spring provides the necessary lip squeeze to compensate for movement in dynamic applications. Spring Energized U-Cups are normally used in single acting dynamic applications and should be oriented with the spring cavity towards the pressure side. Pressure from the media being sealed provides additional sealing force as it acts upon the sealing lips. Spring Energized U-Cups are typically used in applications where conventional elastomers are not acceptable due to application conditions such as: |  |

|

Due to the high performance requirements of the Spring Energized U-cups, most Spring Energized U-cups stocked by Hi-Tech Seals are custom designed parts. Hi-Tech Seals can provide engineering support for seal design on demanding applications. Please contact a Hi-Tech Seals' sales representative with your questions and/or application requirements. |

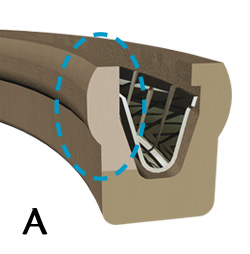

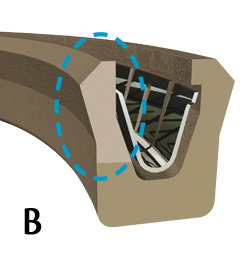

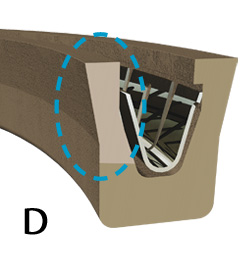

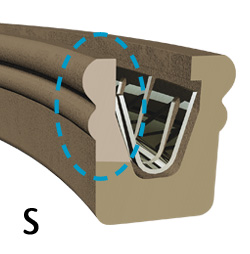

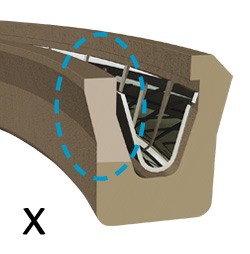

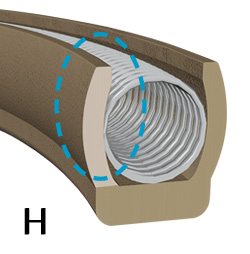

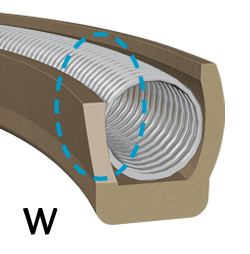

| Selecting a profile: 1. Select the best dynamic lip 2. Decide if the lip is appropriate for the static lip. The Spring Energized U-Cup profile does not have to be symmetrical. 3. Select a spring: A cantilever spring is recommended for dynamic, medium load applications where low friction is desired. A helical wound spring is preferred for static applications or applications where sealability is more of a concern than friction. |

| ||||||||||||||||||||||||

Images are depicted with a Bronze filled PTFE material. |